The 2026 Boston Concrete Survival Guide

A Technical Guide to New England Concrete Longevity by Boston Concrete Works

The Reality of Building in the Hub

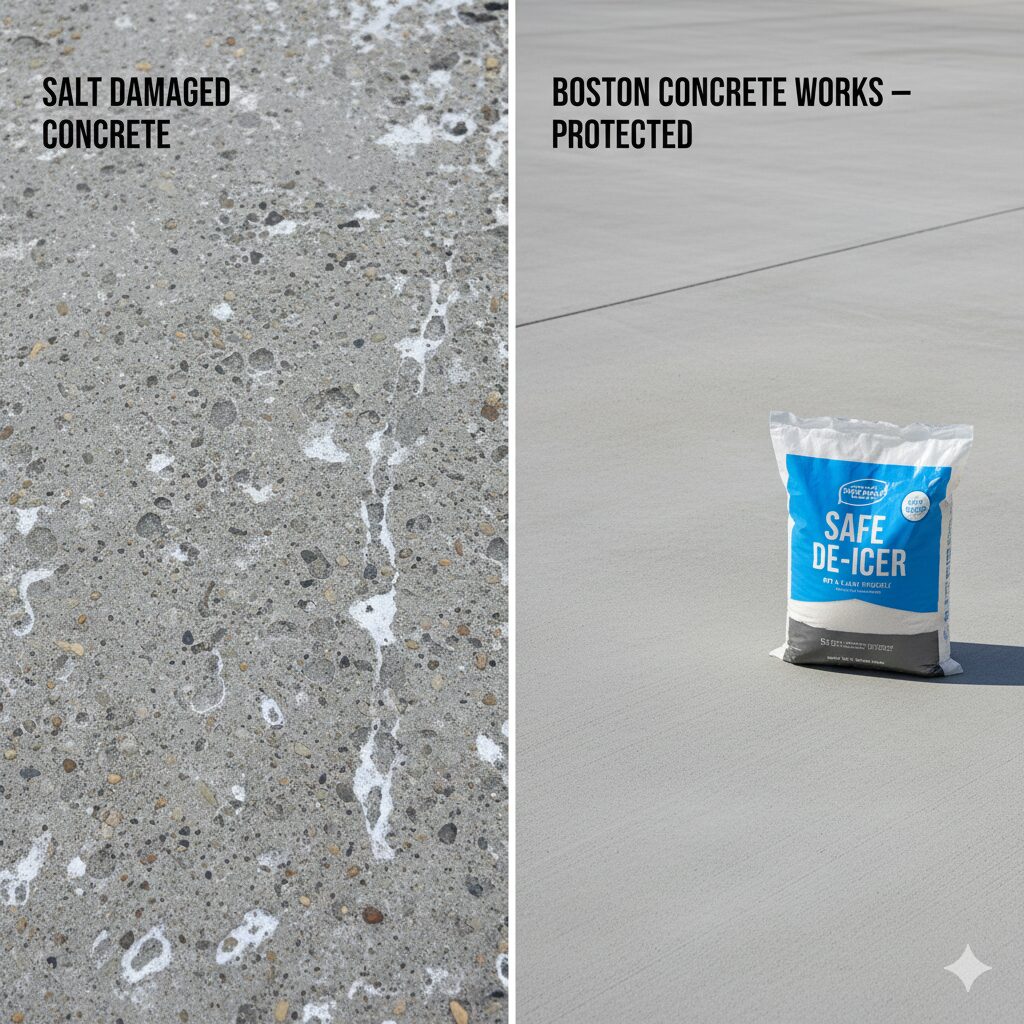

In New England, concrete isn’t just a building material; it’s a living element that must endure some of the most volatile weather patterns in North America. From the humid, salt-heavy air of the Seaport to the deep sub-zero nights in Newton and Brookline, a standard concrete mix simply won’t cut it. Most driveway failures in Massachusetts happen not because of poor usage, but because of “The Boston Stress Test”—a combination of high moisture, chemical de-icers, and radical temperature swings that can shatter a low-grade slab in less than three seasons.

Redefining the Standard for 2026

At Boston Concrete Works, we specialize exclusively in high-performance concrete engineering. Our 2026 approach treats every driveway, patio, and walkway as an engineered system designed for structural longevity. By utilizing Advanced Hydration Control, Climate-Specific Admixtures, and MassDOT-grade density standards, we ensure that your investment survives the winter freeze and the spring thaw. This guide pulls back the curtain on the chemistry we use to beat the New England climate.

Get A Free Quote

Timing the Pour: The Boston Seasonal Outlook

While our technology allows us to pour nearly year-round, each New England season requires a specific engineering approach to ensure the concrete reaches its full 50-year potential.

Spring (April – June): This is a high-performance window for curing, but it comes with “Mud Season” challenges. We focus heavily on sub-grade stabilization and extra stone compaction to ensure the thawing ground doesn’t shift under your new slab.

Summer (July – August): The risk here is “Flash Setting.” High heat can suck the moisture out of concrete too fast, leading to surface spider-cracks. We utilize evaporation reducers and specific pouring windows (early morning) to keep the slab cool and hydrated.

Fall (September – November): This is the “Prime Time” for Boston concrete. The consistent ambient temperatures and lower humidity allow for the strongest possible chemical bond and a perfect aesthetic finish.

Winter (December – March): Safe only with our Winter Protocol. By using heated water batches and R-10 insulation, we can guarantee a full-strength cure even when the ground is frozen in neighborhoods like Newton or Brookline.

Freeze-Thaw Resistance: The Science of Survival

In the Greater Boston area, we deal with thermal cycling. A typical Boston winter sees the temperature swing across the freezing point ($32^\circ\text{F}$) over 35 times. This is the “Freeze-Thaw” effect, and it is the primary reason concrete in Back Bay and Southie crumbles prematurely.

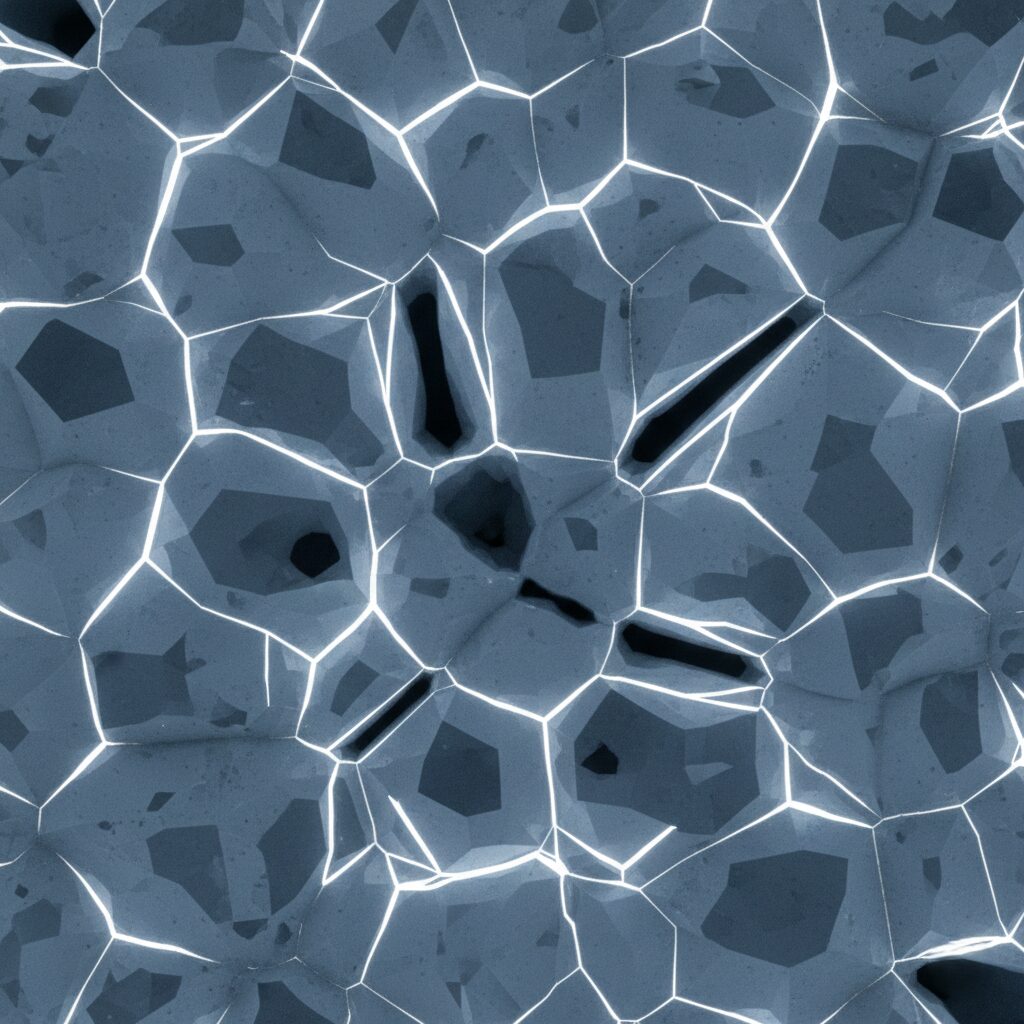

The 9% Expansion Rule: When water enters the microscopic pores of standard concrete and freezes, it expands by approximately 9%. In low-density concrete, this internal pressure creates “tensile stress” that the material cannot handle, leading to surface failure.

The 4,000 PSI Standard: At Boston Concrete Works, we exclusively use 4,000 PSI air-entrained mixes. This higher density resists water penetration, while the air-entrainment adds billions of microscopic “expansion chambers” (air bubbles) per cubic foot.

The Result: When ice forms inside our slabs, it has a safe place to expand into these microscopic bubbles, preventing the “spalling” or “scaling” that ruins standard concrete.

Winter Pouring: The "Heated Mix" Protocol

There is a common myth in Newton and Brookline that you cannot pour concrete after November. We successfully pour all winter long by managing the Heat of Hydration.

140°F Plant-Heated Water: Concrete cures through a chemical reaction (hydration), not drying. If the mix is too cold, the reaction stops. We coordinate with Boston-based batch plants to use 140°F water during the mixing process.T

The 50°F Internal Threshold: Our goal is to keep the slab’s internal temperature above 50°F for the first 72 hours. This is the critical window where the concrete achieves its “Initial Set” and structural integrity.

Non-Chloride Accelerators (NCA): For pours in sub-freezing temperatures, we add NCAs. These chemicals speed up the hydration process without the risk of corroding internal reinforcement.

The Chemistry of Hydration vs. "Drying"

A common misconception among homeowners is that concrete “dries” like paint. In reality, concrete undergoes a complex chemical reaction called Hydration.

When we mix water with Portland cement, it creates a stone-like paste that binds the aggregate together. If this water evaporates too quickly (due to Boston’s summer heat) or freezes (due to a January cold snap), the chemical bond is broken. This results in “dusting”—where the surface of your driveway can be scratched off with a fingernail. At Boston Concrete Works, we use Set Retarders in the summer to slow the reaction down and Accelerators in the winter to speed it up, ensuring the chemical bond is 100% complete regardless of the external temperature.

The Boston Concrete Works Pouring Process

We treat every project as an engineered system. Our 6-step process is designed specifically to handle the soil and climate challenges of the Greater Boston area.

Step 1: Sub-Grade Engineering

A driveway is only as good as its foundation. We excavate organic material and replace it with a heavily compacted crushed stone base. In frost-prone areas like Quincy or Milton, we ensure maximum compaction to prevent the “frost heaves” that snap thinner, poorly-prepped slabs.

Step 2: Structural Reinforcement

We don’t rely on “fiber-only” shortcuts. We install Grade 60 Reinforcement supported by “chairs.” This ensures the steel remains perfectly positioned in the center of the slab to provide maximum tensile strength against New England’s shifting soils.

Step 3: The Custom Batch Order

We don’t use a generic mix. Every order is a custom 2026-spec 4,000 PSI mix with air-entrainment. If the temperature is below $45^\circ\text{F}$, we pull the trigger on our “Heated Batch” protocol, utilizing $140^\circ\text{F}$ water to jumpstart the curing chemistry.

Step 4: Precision Pitch & Leveling

Using laser-level technology, we ensure a minimum 2% pitch away from your home’s foundation. This is a critical step for properties in Cambridge and Back Bay to ensure heavy rain and melting snow flow toward the street, not your basement.

Step 5: The Survival Finish

We apply a professional broom finish for essential slip resistance during icy months. Once the surface “bleeds water,” vanishes, we apply a high-grade Curing Compound. This creates a temporary membrane that locks moisture inside, allowing the concrete to reach its maximum design strength.

Step 6: Thermal Protection Deployment

If your project falls within the “Cold Zone,” our crew immediately deploys R-10 Thermal Blankets. We monitor the local forecast for your specific zip code and keep the blankets on until the slab has safely passed its critical initial cure phase.

Soil Composition and the "New England Heave"

The soil in the Greater Boston area varies wildly. From the clay-heavy soils of Milton to the sandy coastal earth of Quincy, the way the ground holds water dictates how your concrete will perform.

When the ground freezes, the water in the soil turns to ice lenses, pushing the earth upward. This is known as a Frost Heave. If your concrete slab is too thin or the sub-base is poorly drained, the concrete will snap under this pressure. We combat this by installing a “Non-Frost Susceptible” (NFS) base. By using a specific gradation of crushed stone, we allow water to drain away from the slab before it can freeze, effectively neutralizing the upward pressure of the New England winter.

Reinforcement: Why We Use Grade 60 Steel

Many contractors use “Fiber-Mesh” (tiny plastic hairs) and claim it’s a steel replacement. While fibers help with surface shrinkage, they do nothing for structural integrity.

We utilize Grade 60 Rebar, which has a yield strength of 60,000 PSI. We tie this steel into a “Mat” configuration. This creates a skeleton inside your concrete. If the earth shifts or a heavy delivery truck pulls onto your driveway, the steel takes the “Tension,” while the concrete takes the “Compression.” This partnership is what allows a Boston Concrete Works project to last 40+ years while others fail in 10.

Thermal Blanket Technology & R-Value Protection

In the wind-tunnel environments of the Seaport or East Boston, the cold wind can “flash freeze” the surface of a new slab, even if the core is still warm.

R-10 Insulated Blankets: As concrete cures, it generates its own heat (an exothermic reaction). We trap that heat using high-grade R-10 insulated blankets. This acts like a winter coat, ensuring the entire slab cures at a uniform rate to prevent curling.

Subgrade Pre-Heating: We never pour on frozen ground. Boston Concrete Works ensures the sub-base is thawed and pre-heated if necessary, preventing “differential settlement” where the bottom of the slab freezes while the top stays warm.

The "No-Salt" First Winter Warranty

At Boston Concrete Works, we stand behind our engineering, but the first 12 months are the most delicate phase of a slab’s life. Because the internal capillary structure of the concrete is still refining, introducing Sodium Chloride (Rock Salt) can be catastrophic.

The Chemical Attack: Salt is hygroscopic—it pulls extra water into the concrete’s pores. When that water freezes, it creates hydraulic pressure that exceeds the strength of even the best concrete, causing the surface to peel.

Our Warranty Requirement: We mandate a Strictly No-Salt policy for the first winter. This ensures the “Silane-Siloxane” bond has time to fully mature.

The Safe Alternatives: For traction during a Boston Nor’easter, we recommend Plain Sand or CMA (Calcium Magnesium Acetate). These provide the grip you need without the chemical aggression that destroys new concrete.

The Boston Homeowner’s Concrete Maintenance Calendar

Investing in a high-performance slab from Boston Concrete Works is the first step; maintaining it against the New England elements is the second. Concrete is durable, but it is not indestructible. To maximize the 50-year lifespan of your investment, follow this seasonal maintenance schedule tailored specifically for the Boston climate.

Spring: The “Post-Winter” Detox (April – May)

Once the final frost has left the ground in Newton or Brookline, your concrete needs a thorough cleaning to remove the “winter cocktail” of grime and chemicals.

Deep Pressure Wash: Use a pressure washer (approx. 2500–3000 PSI) to blast away the residual salt, silt, and magnesium chloride tracked in from city streets. These chemicals, if left to sit during the humid spring, can continue to eat at the surface of your slab.

Joint Inspection: Check the expansion joints (the intentional “cracks” we cut into the slab). Ensure they are clear of debris. If the joint filler has pulled away, spring is the time to replace it to prevent water from seeping under the slab during April showers.

Organic Stain Removal: If you have overhanging oak or maple trees, remove any leaf piles early. Wet leaves contain tannins that can leave permanent brown “shadows” on your finish.

Summer: The “Sun & Seal” Phase (June – August)

Summer is the time for structural protection. The high UV index in Massachusetts can actually fade decorative finishes and dry out standard sealers.

Visual Crack Audit: Minor hairline fractures (the width of a credit card) can occur as the ground settles. If you see these, don’t panic—but do monitor them. Anything wider than 1/8 inch should be professionally sealed to prevent moisture entry.

Resealing (Every 2–3 Years): If your concrete is no longer “beading” water, it’s time for a fresh coat of Silane-Siloxane sealer. Summer’s dry, consistent heat provides the perfect conditions for the sealer to penetrate deep into the pores and bond chemically with the concrete.

Vegetation Control: Ensure that heavy roots from nearby shrubs aren’t pushing against the edges of your driveway. The hydraulic pressure of a growing root can lift even a 4,000 PSI slab.

Fall: The “Winterization” Prep (September – November)

In Boston, Fall is the most critical maintenance window. You are preparing your concrete for the upcoming “Freeze-Thaw” battle.

Clear the Drainage Paths: Ensure that the 2% pitch we engineered into your slab is not blocked by fallen leaves or mulch. If water pools on the surface before a freeze, you are asking for ice-lens damage.

Final Sealer Check: If you missed the summer window, late September is your last chance to apply a hydrophobic barrier. You want that sealer fully cured before the first Nor’easter hits.

Stock Up on “Safe” Traction: Head to the hardware store now and buy CMA (Calcium Magnesium Acetate) or plain sand. Do not wait until a storm is forecast, or you may be forced to use damaging Rock Salt when the shelves are empty.

Winter: The “Survival” Phase (December – March)

This is where your maintenance habits determine the long-term beauty of your property.

The “No-Salt” Mandate: As part of the Boston Concrete Works warranty, we stress: Never use Sodium Chloride (Rock Salt) on concrete less than a year old. Even on older concrete, salt is a corrosive agent. Stick to sand for grip.

Plastic Shovels Only: Metal-tipped shovels or snowblower augers set too low can “chatter” against the broom finish, chipping the surface. Use plastic-edged tools to preserve the texture of your finish.

Prompt Snow Removal: Don’t let snow sit and turn into slush. Slush is a primary driver of the freeze-thaw cycle, as it keeps the surface in a constant state of saturated freezing.

Expanded Technical Depth: The Molecular Bond

The longevity of a Boston Concrete Works project is determined at the molecular level during the first twenty-eight days of the pouring cycle. Most homeowners assume that concrete is a static material, but it is actually a porous, hydraulic matrix that continues to evolve long after our trucks leave the site. The process of hydration involves the formation of calcium silicate hydrate crystals. These crystals grow and interlock, filling the voids originally occupied by water. If this process is interrupted by premature evaporation in the summer or freezing in the winter, the matrix remains porous and weak, leading to a shortened lifespan.

Furthermore, we address the specific challenge of chloride ion penetration. In a coastal city like Boston, salt spray and road brine carry chloride ions that seek to penetrate the concrete and reach the internal steel reinforcement. Once these ions reach the rebar, they trigger an electrochemical reaction known as oxidation, or rust. Because rust occupies more volume than steel, it creates internal pressure that causes the concrete to crack from the inside out. By utilizing high-density 4,000 PSI mixes, we significantly slow the rate of chloride diffusion, protecting the structural skeleton of your project for decades.

Finally, we consider the role of the modulus of elasticity in concrete survival. In the volatile New England climate, concrete must be rigid enough to support heavy vehicles but flexible enough to withstand the slight movements of the earth during a deep freeze. Our specific aggregate-to-cement ratios are calibrated to provide the optimal balance between compressive strength and flexural durability. This prevents the brittle snapping often seen in cheaper, high-sand content mixes used by residential contractors who do not specialize in the engineering requirements of the Massachusetts landscape.

Concrete Longevity & Winter Survival: Frequently Asked Questions in Boston, MA

In the concrete engineering world, critical strength is reached once the slab attains a compressive strength of 500 PSI. Before this point, if the water in the mix freezes, the ice crystals will physically tear the cement paste apart, leading to immediate structural failure. At Boston Concrete Works, we use 140°F heated water and accelerators to ensure your project hits this 500 PSI safety zone within hours, not days, regardless of the Boston cold.

Longevity isn’t just about weight; it’s about the surface’s ability to withstand friction. Boston winters mean snowplows and salt trucks. By utilizing a 4,000 PSI mix instead of the industry-standard 3,000 PSI, we increase the surface density. This creates a higher abrasive resistance rating, ensuring that metal plow blades and heavy foot traffic don’t grind down the broom finish and expose the vulnerable aggregate underneath.

- Older slabs often crack because they shrink as they lose moisture. To guarantee longevity, we focus on hydration control. By using advanced curing compounds that act as a vapor barrier, we facilitate internal curing. This process ensures that the chemical reaction happens uniformly from the bottom of the slab to the top, preventing the curling or warping that causes traditional concrete to snap under stress.

Is there a difference between water-resistant and hydrophobic concrete?

Yes, and for survival, you want hydrophobic. Water-resistant concrete simply slows down water absorption. Boston Concrete Works recommends Silane-Siloxane treatments that make the concrete hydrophobic—meaning it literally repels water at a molecular level. In a New England winter, this is the difference between life and death for a slab; if water cannot enter the pores, the freeze-thaw cycle has no weapon to use against your concrete.

Thermal shock occurs when a frozen slab is suddenly hit with warm rain or chemical de-icers that rapidly drop the freezing point. This creates a massive temperature differential between the surface and the core, leading to delamination (the top layer popping off). Our survival strategy involves high air-entrainment (6-7%), which acts as a shock absorber, allowing the concrete to expand and contract rapidly without fracturing the surface bond.